Accelerated Aging Calculator - Predict Product Shelf Life in Minutes

The Accelerated Aging Calculator is an essential tool for predicting the shelf life of products under controlled conditions. By using this calculator, you can simulate long-term aging in a short period, saving time and resources. Whether you are working in pharmaceuticals, food, or packaging industries, understanding how a product behaves over time is crucial. This tool allows precise calculations based on ASTM F1980-21 guidelines and helps prevent costly product failures.

For those seeking additional insights, check out ASTM F1980-21 standards to understand how accelerated aging tests are performed. Using the accelerated aging test calculator ensures that your product meets quality and safety standards efficiently.

Accelerated Aging Calculator

How to Use the Accelerated Ageing Calculator for Accurate Results

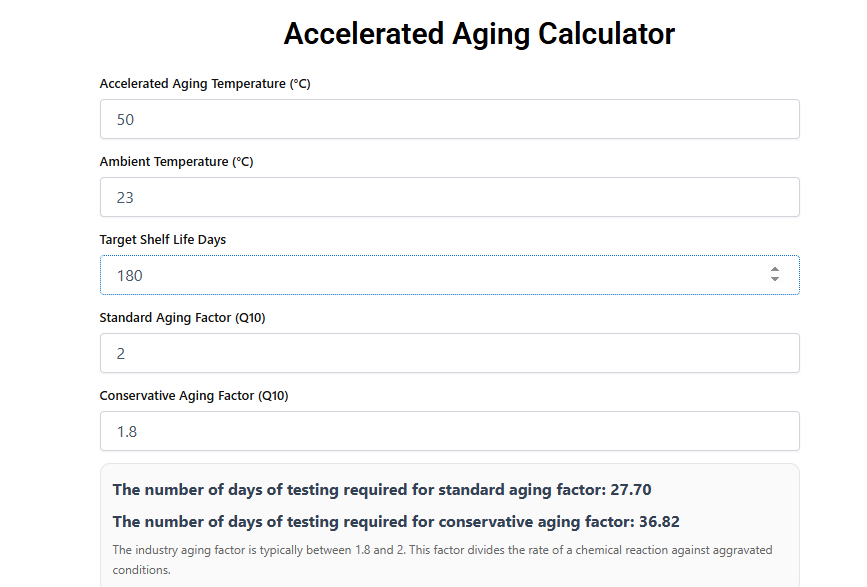

Using the accelerated ageing calculator is straightforward. Input the ambient temperature, accelerated aging temperature, and desired shelf life. The calculator then provides the estimated number of days needed for accelerated testing. This simplifies planning and ensures that your testing schedules align with regulatory requirements.

The accelerated aging time calculator also helps in optimizing storage conditions. By comparing different Q10 values, such as standard (2) and conservative (1.8), you can gauge how sensitive your product is to temperature fluctuations. For detailed calculations and methodology, visit FDA guidance on stability testing.

Step-by-Step Guide to Using the Calculator

Getting started with our accelerated aging test calculator requires understanding several key input parameters that directly influence calculation accuracy. Begin by selecting your product category from the dropdown menu, as different products require specific aging protocols and calculation adjustments.

Temperature input represents the first critical parameter. Enter your intended storage temperature in Celsius, typically ranging from 40°C to 60°C for most accelerated aging studies. Remember that excessively high temperatures may introduce degradation pathways that don’t occur under normal storage conditions, potentially invalidating your results.

Time duration selection depends on your specific testing objectives and product characteristics. Most accelerated aging studies range from 1 to 12 months, with pharmaceutical products often requiring longer evaluation periods. Our calculator automatically adjusts time equivalency factors based on your temperature and duration selections.

Humidity settings become particularly important for moisture-sensitive products. Input your intended relative humidity percentage, typically maintained between 40% and 75% for most testing scenarios. The accelerated ageing calculator incorporates humidity effects through specialized algorithms that account for moisture-mediated degradation reactions.

Product-specific parameters include initial quality measurements, degradation rate constants (if known), and packaging specifications. These inputs allow the calculator to provide more accurate predictions tailored to your specific product characteristics and storage conditions.

Finally, review all input parameters before generating results. The calculator provides detailed output including predicted shelf life, degradation rates, and statistical confidence intervals to support your decision-making process.

Benefits of Using an Accelerated Aging Test Calculator

A reliable accelerated aging test calculator offers multiple advantages. It reduces the time required to study product longevity and helps in making informed decisions about packaging, storage, and transportation. Industries like cosmetics, pharmaceuticals, and food benefit from accurately predicting how long a product remains safe and effective.

To know more, visit USP Stability Guidelines.

Key Factors in Accelerated Aging Calculation

Understanding the key factors is crucial when using an accelerated aging calculator. The most important variables include ambient temperature, accelerated aging temperature, and the aging factor (Q10). Correctly inputting these parameters ensures precise predictions of shelf life.

The accelerated ageing calculator accounts for chemical reaction rates and environmental conditions. Knowing the difference between standard Q10 (2) and conservative Q10 (1.8) can help you prepare for the most extreme scenarios. For further reading, visit ScienceDirect – Shelf Life Studies.

Tips for Improving Product Stability Using Accelerated Aging Calculators

The accelerated aging calculator not only predicts shelf life but also provides insights to enhance product stability. Adjusting packaging materials, controlling storage temperatures, and planning transportation can drastically improve shelf life outcomes.

The accelerated aging test calculator allows companies to simulate different scenarios without wasting months or years in real-time testing. This practical approach is especially valuable for startups and small labs seeking accurate predictions with limited resources.

For additional strategies, explore NIH Stability Studies to understand how scientific methods are applied in real-world product stability studies.

To explore all our tools, articles, and resources visit here.

Image example

Frequently Asked Questions (FAQ) – Accelerated Aging Calculator

Q1: What is an Accelerated Aging Calculator?

A: An Accelerated Aging Calculator is a tool used to estimate how long a product will last under normal storage conditions by simulating long-term aging in a shorter time. It helps industries like pharmaceuticals, food, and cosmetics predict shelf life and optimize storage.

Q2: How does the Accelerated Aging Test Calculator work?

A: The accelerated aging test calculator uses parameters such as ambient temperature, accelerated aging temperature, and aging factor (Q10) to calculate the number of days required for testing. It follows the ASTM F1980-21 formula to provide accurate results.

Q3: What is the difference between Standard and Conservative Aging Factor?

A: Standard Q10 is typically 2, representing the normal rate of chemical reaction. Conservative Q10 is 1.8, providing a more cautious estimate. The calculator shows results for both, helping you prepare for different scenarios.

Q4: Can the Accelerated Aging Time Calculator be used for all types of products?

A: Yes, it can be applied to pharmaceuticals, cosmetics, food, and packaging. However, results depend on accurate input of temperature and target shelf life. Always verify with regulatory guidelines for specific products.

Q5: Why is it important to use an Accelerated Aging Calculator?

A: Using this tool saves time and resources by predicting product stability without waiting for real-time shelf-life testing. It reduces the risk of product recalls, ensures safety, and helps plan better storage and transportation strategies.

Q6: Where can I learn more about accelerated aging standards?

A: For detailed information, visit the ASTM F1980-21 Standards or consult FDA Stability Guidelines. These resources provide comprehensive guidance for conducting accelerated aging tests.